Case Studies

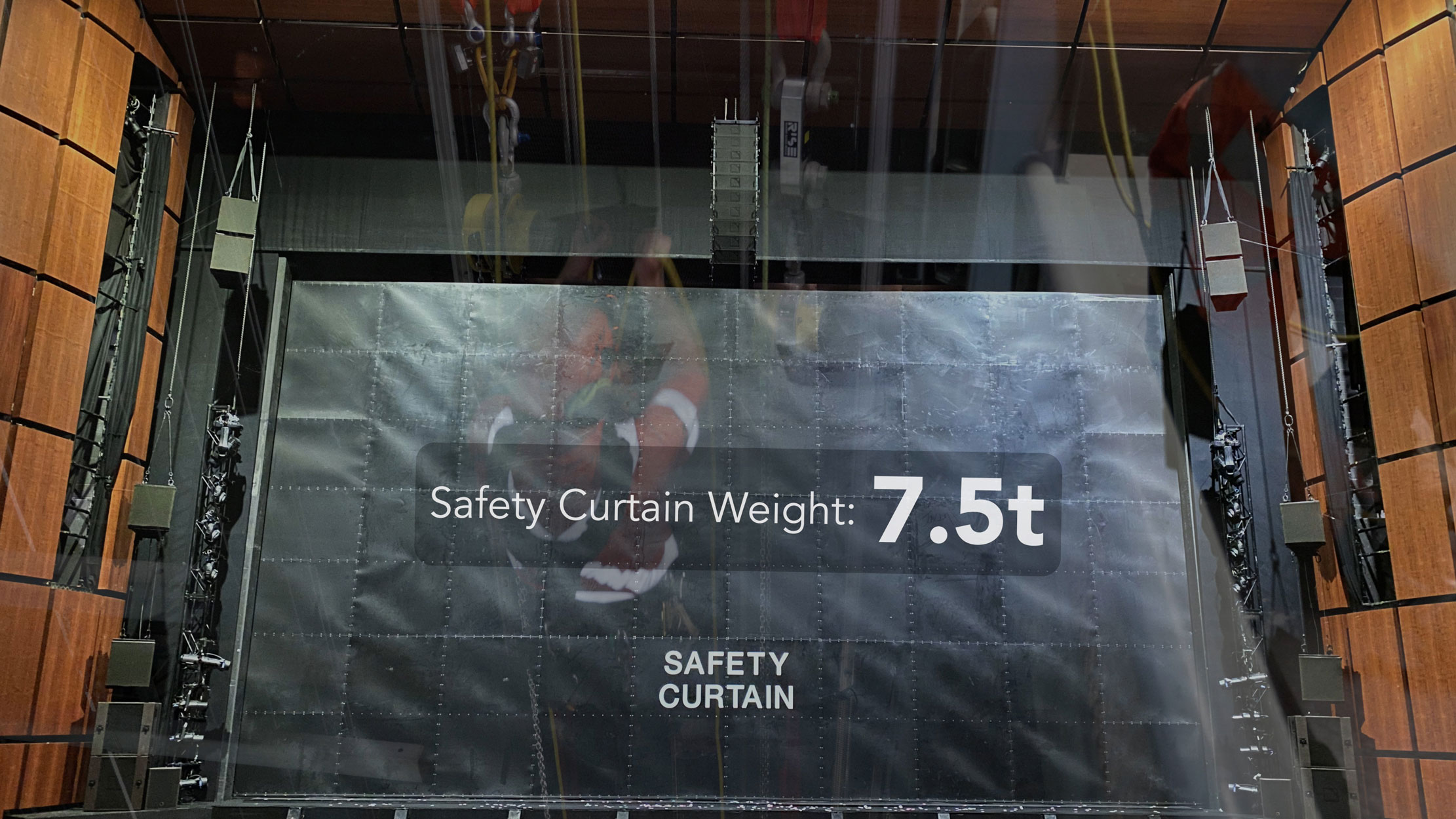

Broadweigh Performs at

The Lyric Theatre, Sydney

The Sydney Lyric is one of Australia’s newest and most innovative theatres. Having recently undergone an $18 million renovation to the auditorium, foyers, bars, ticketing and merchandising facilities, it boasts state-of-the-art facilities throughout.

RISE® Pacific was brought on board by Foundation Theatres to implement a rigging system to temporarily suspend the venue’s 7.5 tonne safety curtain so that maintenance could be undertaken on the sheaves supporting and guiding the wire ropes that the door is typically suspended from. In turn, RISE® Pacific chose to work with Broadweigh to help monitor the loads and assure work was carried out safely.

Clancy Simpson, director, RISE®Pacific said: “As the safety curtain operates as a counterweight system, it was also necessary to temporarily suspend the arbour containing roughly 7 tonne of steel counterweight for the curtain. Using the Broadweigh system allowed continual load monitoring of both the door and arboras it transferred to the temporary rigging so that maintenance work could proceed.”

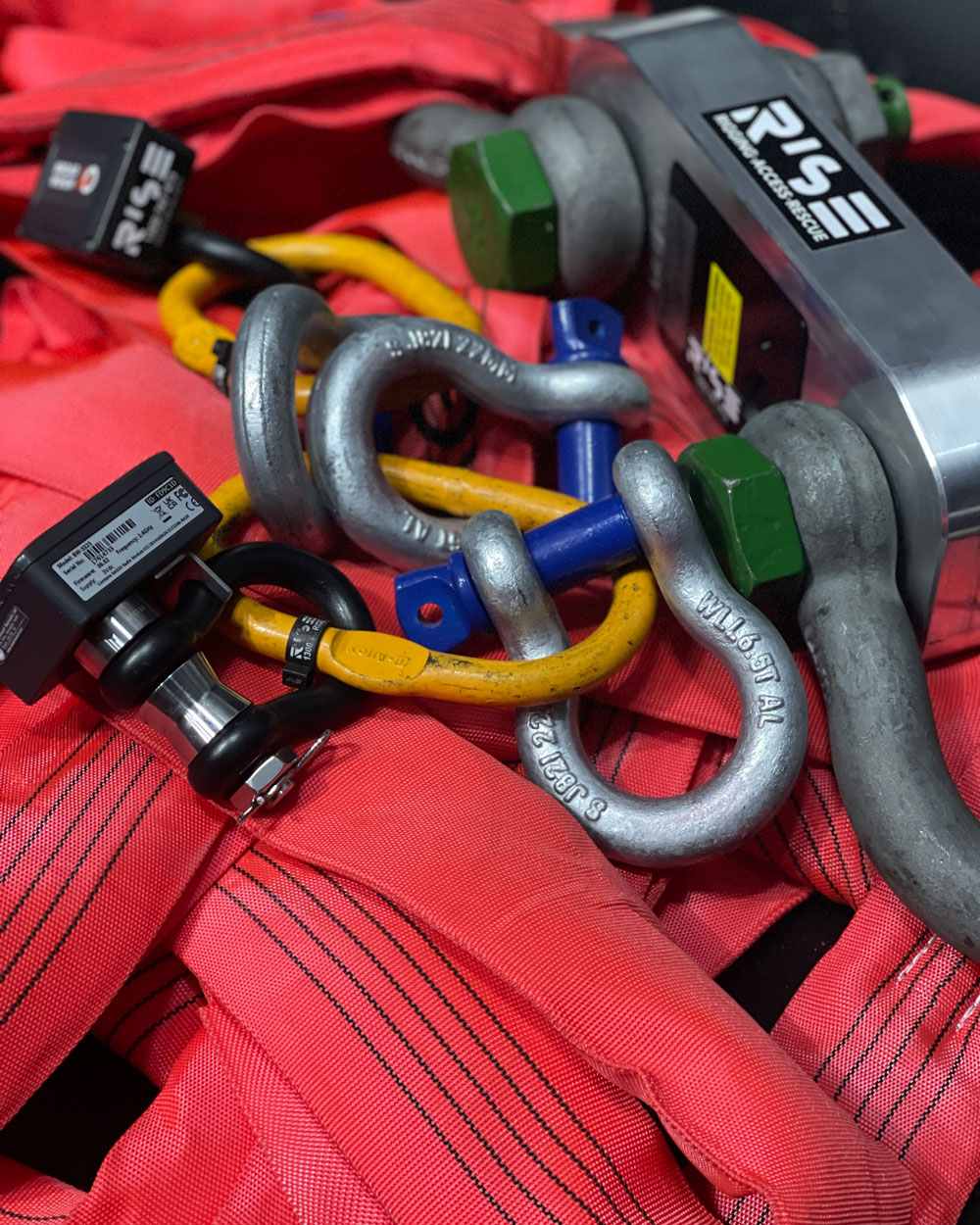

For this project, RISE® Pacific used 8 x 3.2t Broadweigh shackles, with the data being transmitted to the Broadweigh Wireless USB Base Station. The team also utilised the Broadweigh wireless warning module for visual and audible threshold warnings.

With the door being supported from 5 points across its length, and the arbour being supported from 3 points, live load monitoring was also critical to ensure that as the load was transferred to the temporary rigging, proper distribution was maintained, which in turn protected the load, lifting equipment and structural steel supporting the temporary lift from overload or distortion.

Clancy added: “When it came time to return the door to suspension from the counterweighted system, the real-time feedback from the Broadweigh monitoring allowed equilibrium to be maintained between the curtain and arbour, so load was returned to both sides of the system at the same rate. To attempt to complete a complex project like this without the use of live load monitoring introduces many unknowns that make it nearly impossible to guarantee the safety and success of the lift. Without a system like Broadweigh, loads maybe improperly distributed, lifting equipment could be overloaded and the structure could be loaded in excess of the parameters provided by consulting engineers.”

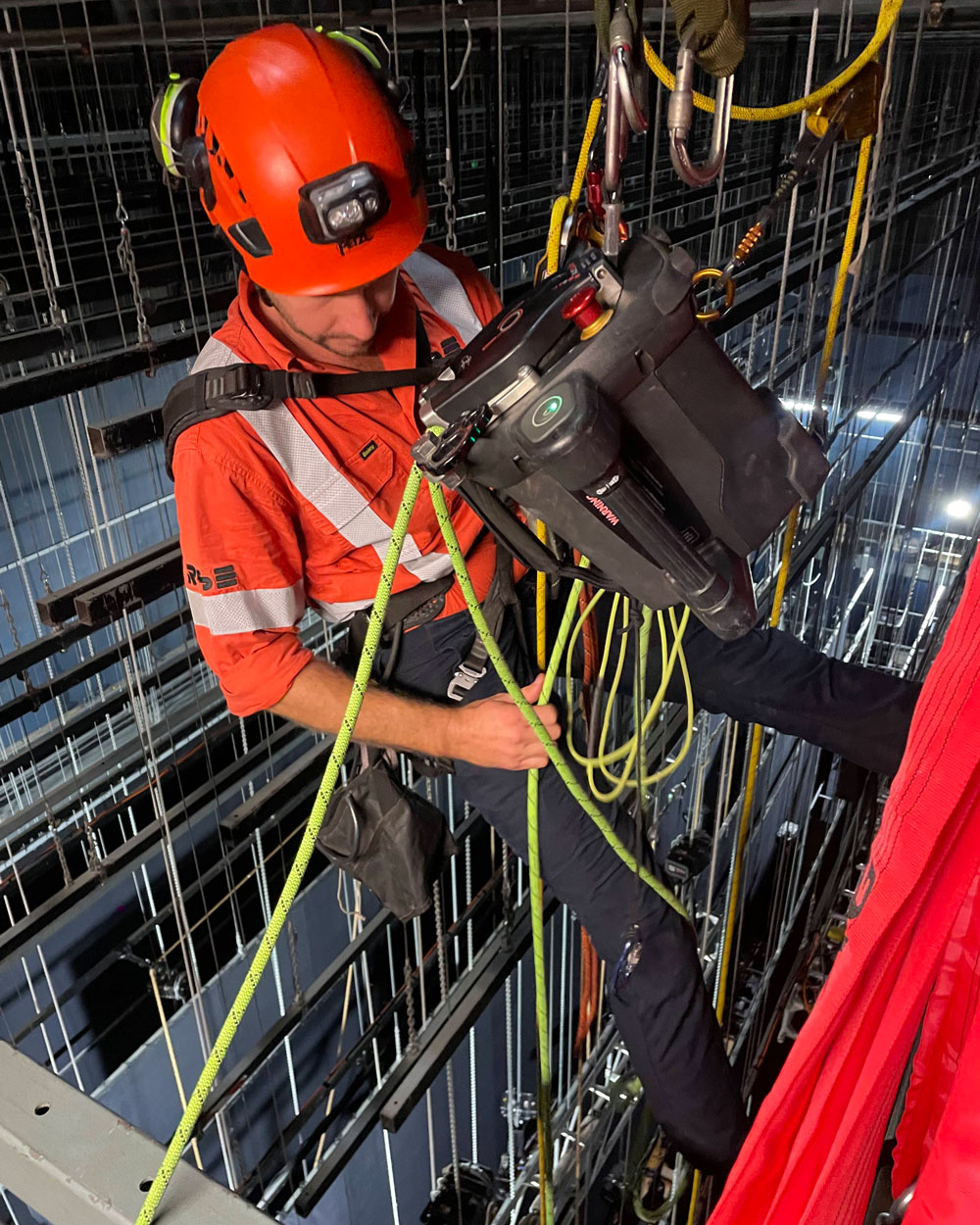

On site, the readings provided by Broadweigh were monitored by each individual member of the team from their personal mobile device. This allowed constant visibility as the lift of the curtain and arbour was completed. Being able to monitor the loads in real-time made it easy for the technicians to confirm the full transfer of the load and distribution of it between lifting points. Calculations run within the Log100 software, displayed this distribution by expressing each points load as a percentage of the total load.

Dane Boulton, design and sales at RISE® Pacific explained: “Broadweigh’s fully wireless system allows for rapid deployment on site. Minimising the time spent implementing the system and maximising the time spent reaping its benefits, Log100s ability to fully customise the readout from the cells, perform arithmetic with the cells values and input these values into expressions, allows the creation of project specific interfaces, which in turn allow the data to be easily and clearly viewed and interpreted, depending on the operations taking place.”

Using the Broadweigh system allowed RISE® Pacific to demonstrate to its client and other stakeholders including consulting engineers and other contractors, its commitment to safety and best practices.

Dane concluded: “Broadweigh provides us with a transparent way for these stakeholders to get a better understanding of exactly what is taking place and it is awesome when our clients view the data on the monitor and it prompts great discussions about the project, our process and the equipment being used.”